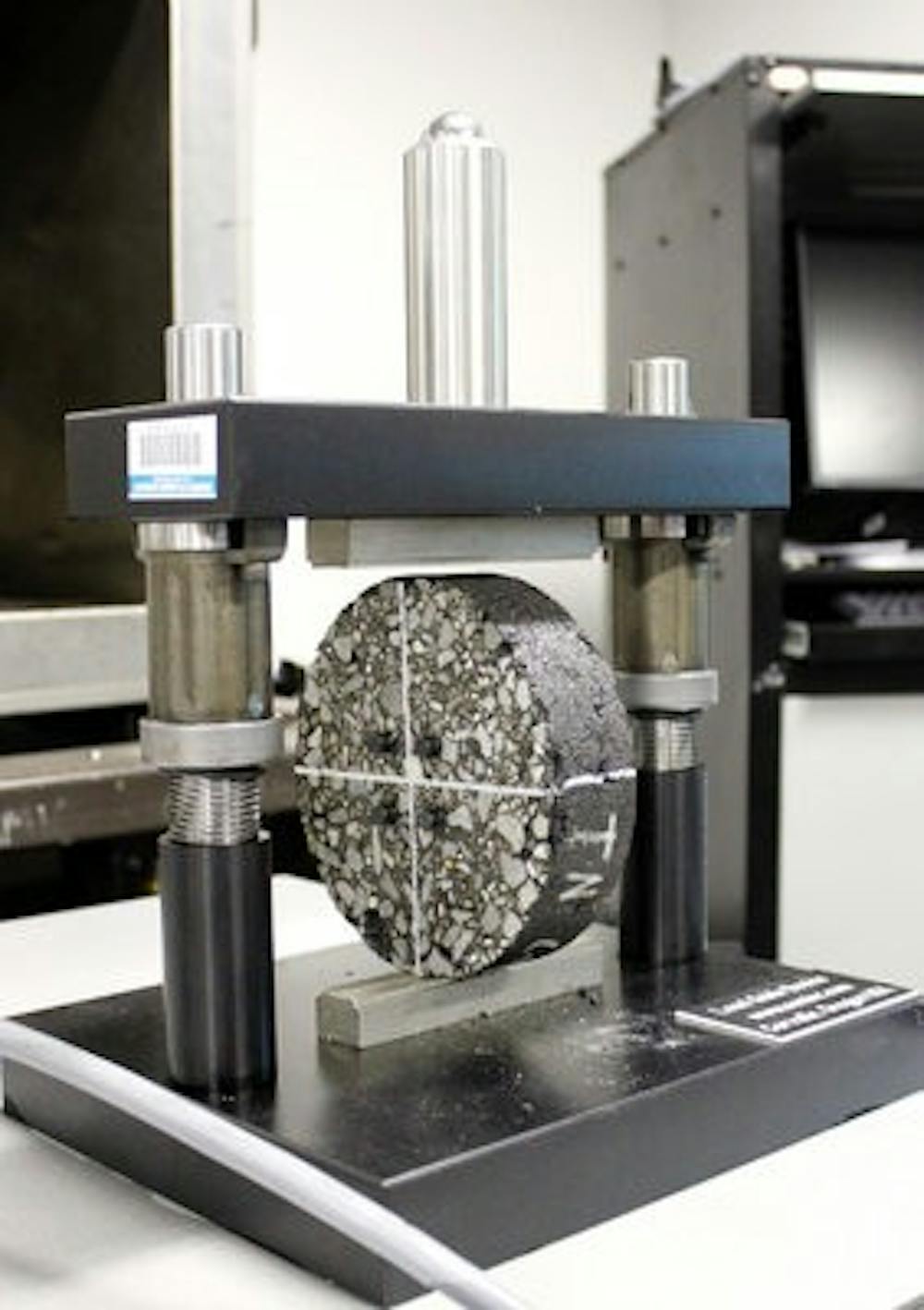

Reclaimed asphalt pavement, RAP, is one of many recycled materials tested at the National Center for Asphalt Technology at Auburn University.

"The NCAT and its unique programs represent the best in cutting-edge technologies in the field of asphalt research and education," said Jim Killian, director of communications and marketing for Samuel Ginn College of Engineering. "Millions of dollars have been saved, safety has been increased and innovations in recycling have made this a green industry."

When an old asphalt surface is scraped up, the product is gravel-sized aggregate chunks, which are characterized as RAP.

RAP is the No. 1 most recycled material in the world, said Andrea Kvasnak, lead research engineer for NCAT.

RAP is processed into two categories, fine and coarse, according to the size of the pieces.

"State agencies typically allow mixes containing 15 to 20 percent RAP in surface mixes," said Randy West, director of NCAT. "(We are) paving our way to a more sustainable future."

Other recycled materials being tested are roof shingles, old tires, steel slag and sulfur.

Some states do not allow the recycling of used shingles in the asphalt mixture. They only allow the use of new shingles that were intended to be put on a house but were leftover following the construction. "Crumb rubber (old tires) can be added to the pavement to help with the flexibility of the pavement," Kvasnak said. "It actually boosts the performance of the road." Steel slag is used in the same fashion as RAP, as an aggregate. The steel slag does not rust because it is coated in the oil based asphalt.

NCAT not only tests recyclable materials, but they also test certain additives that reduce the asphalt's melting temperature.

"(We are studying) technologies to reduce fuel usage and emissions in the process of producing asphalt pavements," Kvasnak said.

Asphalt has to be heated to 300-350 degrees Fahrenheit before it can be mixed and paved as a surface.

Asphalt binders (called additives) are added to asphalt mixtures to reduce the viscosity. Viscosity refers to the fluid nature of a substance, so asphalt binders make the mixture flow easier when the asphalt is heated.

With additives, the asphalt is a warm mix because it melts at lower temperatures, 185-200 degrees Fahrenheit, compared to the mixture without additives.

The asphalt binders include wax and a silicate mineral called zeolite.

Wax is mixed with asphalt to reduce the melting temperature and zeolite is mixed, making the asphalt mixture expand as yeast does in dough.

The zeolite can hold 20 percent moisture.

When the water in the zeolite mixes with asphalt, the water vaporizes, creating bubbles that makes the asphalt foam up, Kvasnak said.

"Asphalt roads can last more than 20 years if they are constructed properly and good maintenance occurs," Kvasnak said.

The asphalt mixtures are tested at the NCAT Pavement Test track in Opelika.

The track is oval and consists of 46, 200 foot-long sections allowing for 46 mixture tests at a time. The track is 1.74 miles long.

Semitrailers drive around the track to test the mixtures.

Kvasnak can be contacted at ank0004@auburn.edu or 844-7303 for more information.

Do you like this story? The Plainsman doesn't accept money from tuition or student fees, and we don't charge a subscription fee. But you can donate to support The Plainsman.