The University is set to receive a $3 million grant from the U.S. Department of Commerce to research and

U.S. Sen. Richard Shelby, R-Alabama, announced the award yesterday, which will be supplied from the Commerce Department's National Institute of Standards and Technology.

"This is a large grant from a large federal agency," Auburn President Steven Leath told The Plainsman. "It's not only going to allow us to do some tremendous work in additive manufacturing that we wouldn't have been able to do without the grant, but it puts us up on the national profile as a major research institute."

Shelby also commended Auburn as a national leader in the field.

“This NIST grant will provide

The University will work to address various issues facing the industry including an initiative that will conduct cutting-edge research and educate graduate and undergraduate students all while developing and promoting technological innovations that will hopefully advance the pace of the additive manufacturing industry.

"We've had some areas of research with real successes like in the additive manufacturing process that makes nozzles for jet engines, but that's just one example of where we could go," Leath said. "With our large interest with the space program, if we could refine the additive manufacturing process, when astronauts are gone for months and years at a time, they would have the ability to make what they want and need while they're gone."

Leath said the University wants to take its contributions in certain industries, like aviation, and transfer those to other sectors, like the space industry.

The new funding will give Auburn's National Center for Additive Manufacturing Excellence money to expand its programs to include new research on metrology, which is the measurement and characterization of 3D-printed parts. And advanced process models will allow engineers to predict the properties and performance of those parts.

Shelby said the research using this grant will have a strong technical and economic impact on various industries in the United States.

And Auburn could continue to make use of its strong partnership with NASA.

The University founded the National Center for Additive Manufacturing Excellence in collaboration with NASA. The University is already doing groundbreaking research and development to advance industrial technology and provide standards to help the new sector grow. The center is also developing the future workforce needed to keep the industry productive and profitable, Leath and Shelby said.

During Leath's installation as University president in March, he promised to make Auburn a premier research institution as part of one tenant of his three-pronged "Inspire. Innovate. Transform." vision for the University.

He told The Plainsman Thursday that this grant is evidence the University is moving in the right direction.

"This is exactly what we want to be doing — large grants where Auburn is the principal investigator and not a secondary investigator," Leath said. "It also solidifies our partnership with the federal government."

In many ways, Auburn is already leading the way in additive manufacturing research.

Last year, GE Aviation — a multinational, multibillion-dollar aviation manufacturer — chose Auburn to participate in the GE Additive Education Program. As part of that program, the University received a state-of-the-art Concept Laser MLAB 100R metal printer.

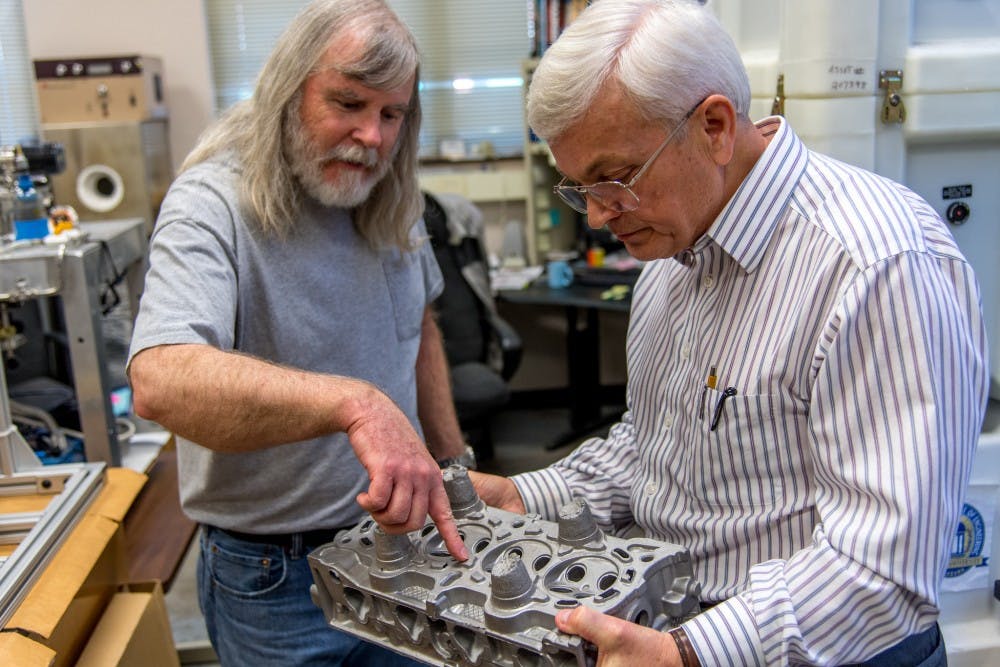

The University's additive manufacturing engineering faculty, including materials engineering professor Tony Overfelt, director of the Center for Industrialized Additive Manufacturing,

That 2016 grant focuses on researching ways for smaller manufacturers to incorporate additive technology into their processes.

And over the last several years, Auburn has hired additional faculty with expertise in the field, including more than 20 faculty members specializing in that area, according to the Alabama Department of Commerce. The University president also promised to hire additional faculty for similar research across the University's campus.

Leath said the grant wouldn't have been possible without Shelby's influence.

"Sen. Shelby has been a great partner in this," Leath said. "He has advocated for research funding and he has advocated for this program. This is exactly the track we want to be on."

Grants that lead to more research on Auburn's campus also benefit undergraduate students, too, he said. They'll be able to take part in the research and gain valuable experience.

"The more our faculty is on the edge of science and engineering, they bring that into the classroom," Leath said. "It also brings opportunities to work as undergraduate researchers in their labs and gives them first-hand experience related to the industry and the jobs they are going to have when they leave. It just enhances the experience of learning here at Auburn."

Managing editor Lily Jackson contributed reporting to this piece.

Do you like this story? The Plainsman doesn't accept money from tuition or student fees, and we don't charge a subscription fee. But you can donate to support The Plainsman.

Chip Brownlee, senior in journalism and political science, is the editor-in-chief of The Auburn Plainsman.